|

|

Photo by Pontus Johansson |

“If we’re going to use a product in a circular economy, we must consider it from the design phase.” This message is becoming a kind of mantra among professionals involved in the transition towards a circular economy. In this case, the quote belongs to Marcus Wendin, an expert on Life Cycle Assessment (LCA) who has been using this method for environmental assessments since 1998, when he started working at Volvo Technology. Since 2003, he has run his own company, Miljögiraff, which advises businesses about the environmental impacts of their products, from a life cycle perspective, and on how to develop sustainable alternatives.

LCA may sound familiar to many, but few have as much experience in the field as Wendin has. Through his personal experience, he provides concrete examples of LCA through case studies, explains what the trickier parts to using the method are and, in short, how to increase circularity in society. For Wendin, one of the keys to a successful transition is questioning established norms.

What kind of clients request your LCA services?

“We usually have industrial clients who want to know how to reduce the environmental impact of their products in their whole life cycle perspective. They want to know if there are any trade-offs between the use and production phases, for instance.

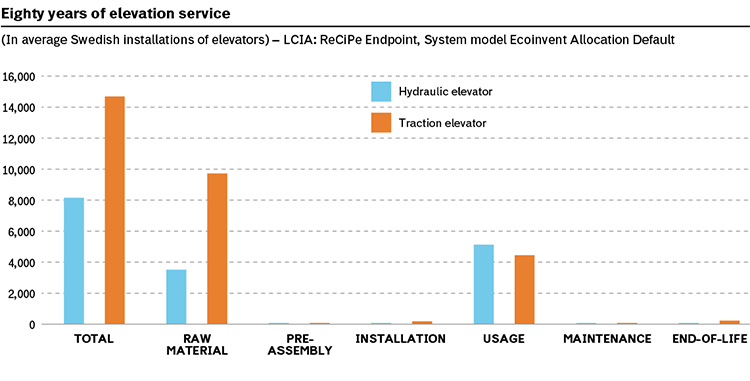

One of the most emblematic cases we had was a company that produces elevators. Wire-driven elevators are the most common concept of elevator and, for most people, they are the preferred option from an environmental perspective, because they use less energy. A client asked us for act-based information on that, because his company was selling an elevator working with hydraulic pressure, which regulates the elevator instead of the wire, and uses a little bit more energy every time you travel with it. But the trade-off here is that it requires much less material for the production, because, for example, it doesn’t need the counterweight of a wire elevator. So if you compare a wire and a hydraulic elevator during the life span of a building, say 80 years, you will come to the conclusion that the environmental impact of the hydraulic elevator is actually half over the entire period.”

How did this discovery impact the company?

“It was very important for the company, which was a rather small company and has now doubled in size. However, the result of our study also changed the branch standard for elevators, as well as the regulations for buildings and the Eco-design Directive from the European Parliament.”

So what are the main elements you have to pay attention to if you want to perform a successful LCA?

“The first thing would be to focus on the functional unit so as to create a model that is relevant for comparison. You need to know what kind of function or service the product provides, and what would be the alternative to this product.

Particularly at the beginning, there is a risk of placing too much focus on the inventory of data. It’s better to spend more time understanding the goal and scope of the system. You should draw your system more roughly as a starting point and make sure that everyone has agreed on the goal and scope before you start collecting data. This is so time consuming that you risk spending too much time on the wrong details. So, I would recommend that everyone performing an LCA make a quick and easy rough estimate first, and then, when you know exactly what you’re about to study, dig deeper into the data.”

Could you share some results that have surprised you?

“Definitely. The hanger is a very good example. We had the opportunity to help a client who produces hangers for clothes from paper. At first, obviously, the client thought that this would be a much better hanger from an environmental perspective than a plastic one made of polystyrene, which are used more frequently. So we made this comparison.

The first thing we noticed was that steel details in the hanger were very important; using recycled steel is highly recommended. When comparing plastic and paper, we considered that the plastic hanger would be properly recycled within a circular economy model, and we would never buy virgin material. It turned out that recycling the plastic is actually better than using virgin paper for producing hangers. That was very interesting. It tells us something in general about products that are made out of plastic: it’s very important to create a system that recycles all plastic products, and not only packaging. Certainly, the circular economy can play a very important role in this.”

Does this mean that for LCAs you choose an ideal scenario where materials are recycled?

“We actually create different scenarios including incineration and municipal recycling, among others. It’s very important to know if the product has a controlled end-of-life or not. In the hangers case, it was a clothing store, so they had a controlled end-of-life scenario. In that case, it is almost always more efficient to use recycled plastics, but if you don’t have a controlled scenario, it’s better to use a product that doesn’t have such a significant climate impact when you send it to incineration. That would be the paper hanger.

It is important to focus on the big flows of things. For example, stores use approximately five hundred million hangers every year, but the end user doesn’t use that many hangers. So when it comes to hangers it’s more important to consider their use in stores. That goes for a lot of products; it’s important to focus on the big flows.”

What are the main changes needed for more sustainable products?

“After 20 years doing LCAs, I had time to notice that, in general, if we want to make a change, we should focus on the social or normative behaviours. We are often locked in our minds and think that how things work is how they should work. We tend not to question why things are working as they are. I think, for example, that legislation can sometimes hinder us from thinking outside of convention and norms.”

What kind of legislation are you referring to?

“Let’s see. We can take the case of the elevator, for example. Since most people think that wire-based elevators are the best, that has also been written into the prescribed criteria. So when you build a house with an elevator, it’s prescribed already from the beginning that a wire elevator is less energy intensive. But from a lifecycle perspective that is not true. You really need to question how this system is set up to come to that conclusion.

Another example could be medical products. If we would like to reduce or recycle a material that has been in a hospital, it is often not even allowed. We have to question these social norms, because very often we actually can recycle a material or even reuse a component without increasing the risk of hygiene issues.

For example, blood bags that are used when a patient is losing too much blood are usually produced in PVC plastics. That’s great, it has saved many lives. However, now it is actually possible to create plastics that are much better than PVC, without, for instance, softener substances used in PVC plastics that can cause hormone disruption. Most people think that we should stick to PVC, but if we question this assumption we can find solutions that are so much better for the patient. We could reduce the risks of getting cancer or fertility defects, among others.”

So carrying out a LCA is about much more than assessing individual products…

“When we perform a LCA we have to question the legislation in place and propose that things could be different. Circular economy is fantastic, because it changes the perspective from which we think about products. LCA can be a tool to verify if the circular economy is really the preferred option. But, we have to be prepared to make the circular economy concept a little bit more complicated than it is right now. We tend to think that materials are recyclable an eternal number of times and that products can be the same even if we use them hundreds of times. If we’re going to use a product in a circular economy, we must consider it from the design phase.

Regulatory pressure is very important and, when it comes to the circular economy, I think we need to push people to question the social script of things. I can see from my experience that the companies that have been innovative and started early with the circular economy have been much more prosperous and at the same time better for the environment.”

Miljögiraff, www.miljogiraff.se