Forty million cells and only 0.16 grams per cubic centimetre. Around 90% air. These are some of the characteristics that make every single piece of cork unique. A naturally derived material that has an ancient bond with man, made of patience, knowledge, and tradition. For oak cork to be employed as a cork stopper, it has to “mature” for at least 43 years before it gains the necessary physical and chemical characteristics needed for the sealing of a bottle, thus assigning the role of improver to time itself.

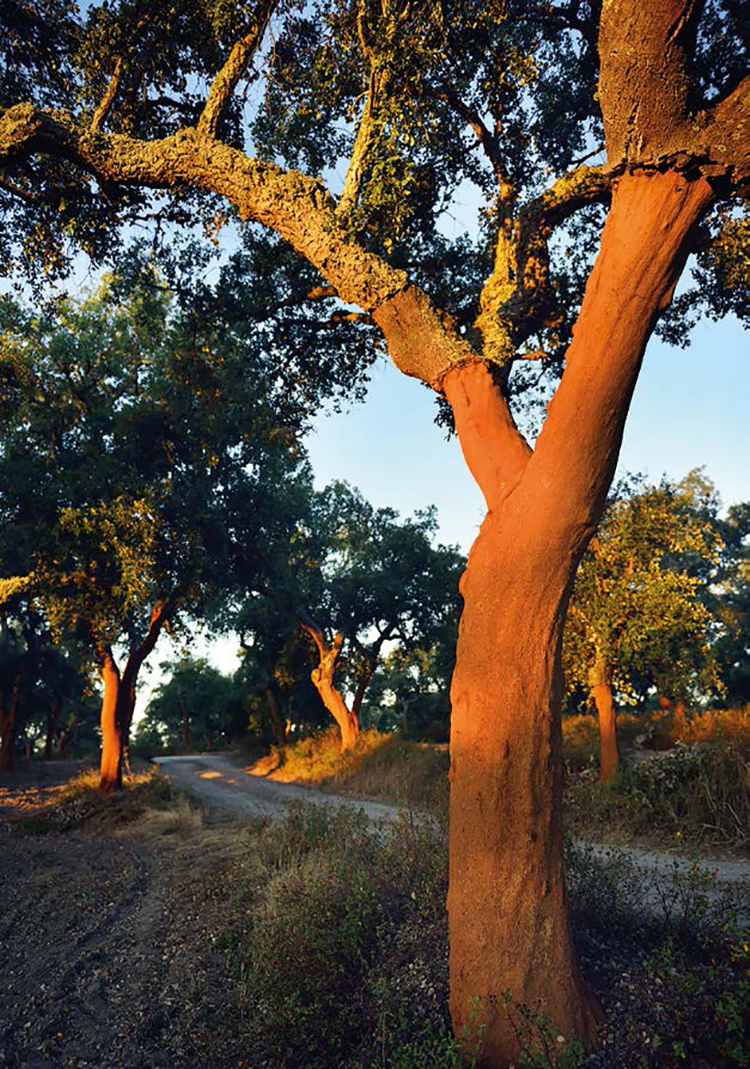

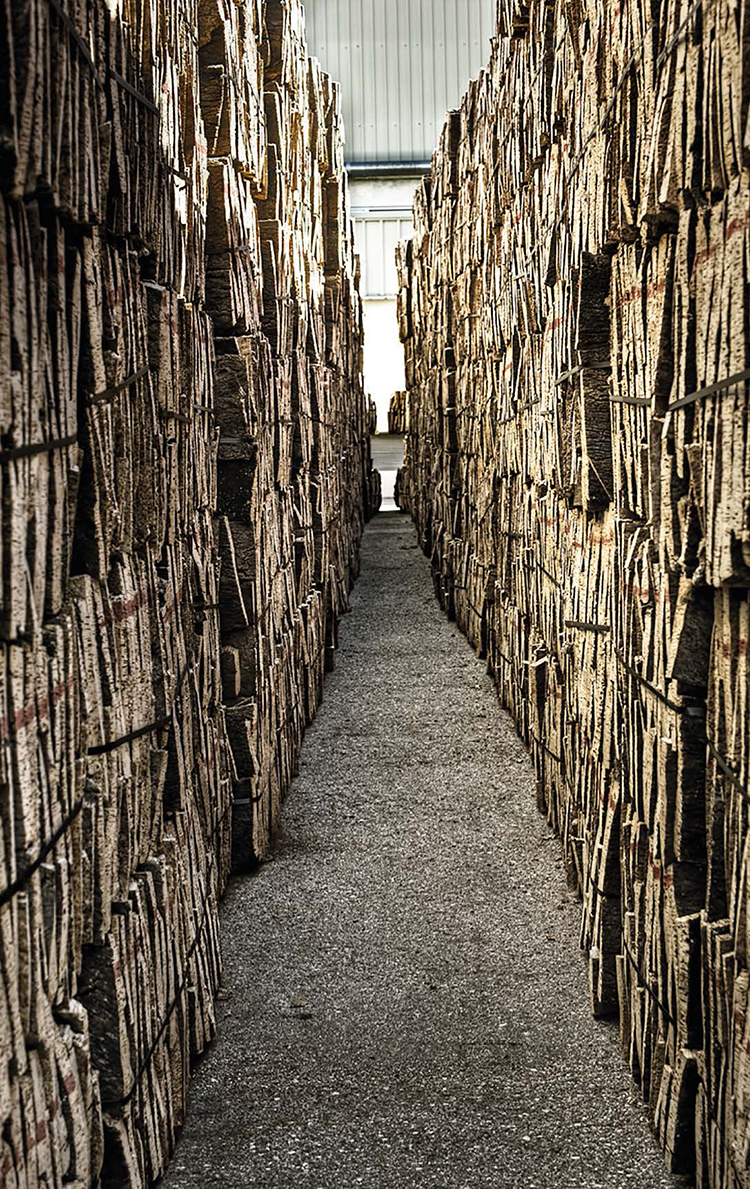

Extracted from the outer part of the cork oak’s bark (Quercus suber) it is composed mainly of suberin, lignin, polysaccharides, cervids and tannins, that make it a waterproof material, that is also extremely flexible, elastic and practically incorruptible. Produced from phellogen, a layer of cells that dividing themselves create a barrier, oak cork is able to regenerate itself at each removal of the bark and hence produce a new layer of bark, or rather new layers of cork. To get the first removal of bark the tree has to be at least 25 years old, over 1.30 meters high and have a circumference of at least 70 centimetres, whereas all subsequent removals of bark occur every nine years, thus giving the tree time to regenerate. Here is where the topic of time enters the relationship between man and cork, as a typical Portuguese saying demonstrates: “plant a eucalyptus for yourself, a pine tree for your children and a cork oak for your nephews.” In fact, a cork oak can live up to two centuries, an assured inheritance for future generations.

The cork industry, between innovation and tradition

Cork oak grows naturally in the Mediterranean basin, in particular in Spain, Portugal, Marocco, Alegria and Tunisia, as well as in the southern coast of France, the western coast of Italy, Sardinia and Sicily. The total surface area occupied by cork oak plantations is of 1.44 million hectares in Europe – half of which is found in the Iberian Peninsula – and 700,000 hectares in North Africa. Portugal is the land of cork, with over 730,000 hectares, most of which concentrated in the geographical area of Alentejo. “Today, Portugal produces around half of the world’s cork, whilst the average density is of only 50 plants per hectare, in a naturally occurring propagation,” explains Carlos Veloso dos Santos, general director of Amorim Cork Italia, a branch of the large Portuguese group that is among the market leaders in cork stoppers.

In cork oak plantations there is a different type of cultivation compared to other forestry methods, at least until today. Consequently, production is intertwined with the natural cycle of plants. However, it has been discovered, almost by chance, that a cork oak that is watered constantly with a drip irrigation system can become an adult in just 8 years, instead of 25. “This means that the first removal of bark can already occur at 8 years of age, and by consequence cork that is suitable for the production of bottle corks is ready in 21 years, instead of 43,” explains Carlos Veloso dos Santos. “This means that in around 50,000 hectares we could have approximately 30 million new plants, which would increase production by 30%.” An increase that would benefit not only employment, that to date sees 9,000 employees, but also for the Lusitania territory, which is ever more prone to desertification and devastating fires. In fact, at a difference to other tree species, after a fire the cork oak’s branches, protected by this very material, remain alive and are able to re-sprout and grow back.

Cork, sustainable by nature

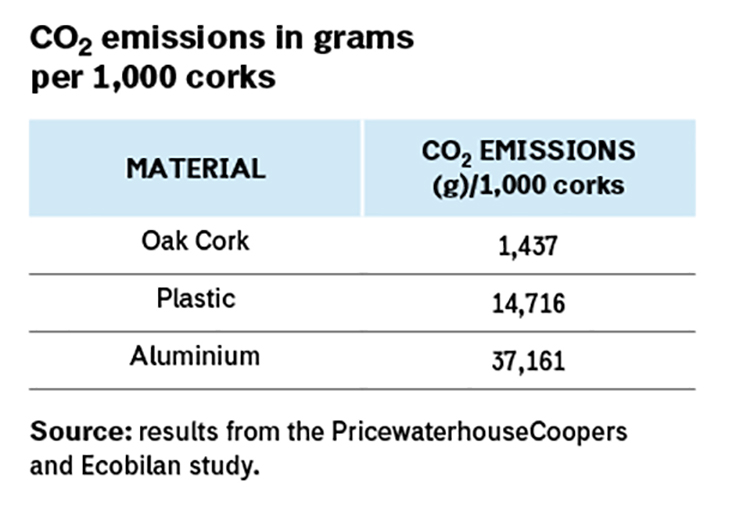

Over the years, particularly in the wine sector, a new market for corks has developed, specialised in the use of aluminium (screw on caps) and plastic polymers. However, if we perform a lifecycle assessment of the materials used starting from the raw materials extracted, through to their processing and up to the end of life phase; oak cork remains the solution that offers the smallest environmental impact. According to results reached in a study conducted by PWC and Ecoliban and sponsored by Amorim, a plastic cork, which is therefore derived from fossil fuels and not a renewable source, is responsible for 10 times the amount of greenhouse gas emissions compared to oak cork, whereas in the case of aluminium the amounts are even greater and can reach up to 26 times more emissions. The study also demonstrates how oak cork is the best alternative in terms of non renewable energy consumption, CO2 emissions and eutrophication of surface waters, acidification of the atmosphere (with the production of nitrogen oxides and sulphur dioxides) and finally in the production of waste. Only in terms of water consumption is oak cork a worse solution than aluminium, but still better than plastic. Without considering the end of life aspect: oak cork is a natural material that biodegrades in nature. Plastic and aluminium have to be collected correctly so that they can then, in best case scenarios, be sent on for recycling.

There is also the presence of an absolute value that is of substantial importance, especially in the age in which we live: the ability for carbon sequestration in plant matter. This means that cork oak, during its growth, assimilates carbon dioxide, and sequesters carbon throughout its lifecycle. It is estimated that processed cork continues to withhold around 1.7 grams of carbon per oak cork or the equivalent of 6.2 grams of CO2. According to Felipe Costa y Silva, of the Portuguese Institute of Agronomy (ISA), “in a cork oak plantation with a good productivity in the central region of Portugal, for each tonne of cork extracted, the oak forest can contribute to the carbon sequestration of 73 tonnes of CO2.”

The TCA question

TCA (2,4,6-tricloroanisolo) is a chemical compound that is present in nature, in wood, in wine, in water, in soil, in vegetables, in fruit and even in cork. This compound is one of the principal factors responsible for the issue of moulds that can develop in cork and then give wine that “cork taste.” The cork industry has worked hard to reduce the presence of this compound, and today can guarantee almost all their cork products. “For example, today with the NDtech system we are able to analyse a single cork every 10 seconds, so as to guarantee 125 million corks per year,” explains Carlos Veloso dos Santos. “Considering that globally 150 million bottles of high quality wine are produced per year, we want to open a potential 125 million bottles of wine by 2020, all of which guaranteed.” However, this is a method that is dedicated specifically to the top quality corks. What about the others? “Amorim – continues Carlos Veloso dos Santos – has established a project that aims to eradicate TCA completely from its products by 2020. In this way we will be able to guarantee that 99% of our corks are TCA free and only 1% with a maximum of 1 nanogram. This means that wine will have almost no chance of being altered.”

The alternatives on the market

In the world today only 15% of plastic is collected and sent on for recycling. In Europe this statistic is a little better, whereby the rate of recycling reaches 30%. However, globally more than half of plastics end up in landfills, whereas 25% are used for energy recovery. Confronted with these figures, many companies are working, some of which successfully, to find alternatives to plastic polymers derived from fossil fuels with those derived from renewable sources, such as biomass. Even in the world of corks for wine bottles this is happening and today the market proposes a significant range of bioplastic corks, realised using base materials such as ethanol derived from sugar cane. However, over the years an important body of academic research has demonstrated that the constant increase in agricultural areas that are subject to the intensive cultivation of sugar cane, has produced serious environmental repercussions. According to a report by the Evidence and Lessons from Latin America Institute (ELLA), that works to create plans for development and cooperation in South America, Asia and Africa, “the expansion of sugar cane in Brazil has been revealed to be unsustainable because of the lack of knowledge surrounding biodiversity and adequate laws to protect it. Researchers such as Martinelli, Smeets, Bernard and Almeida, amongst others, especially in Brazil, have demonstrated that the environmental impacts associated with the production of ethanol in Brazil have been important obstacles for the production of sustainable biofuels.” Even environmental associations like the WWF report that the production of sugar cane generates “environmental impacts through the loss of natural habitat, the intensive use of water, the heavy use of chemical products for agriculture, the discharge and flow of toxic effluents and pollution,” with obvious impacts on wildlife, soil, and entire ecosystems. Not only, the entire supply chain often comes with stories of exploitation and working conditions that are on the edge of disrespecting basic human rights. A recent report published by the Mani Tese association, revealed “undeclared or contract less working relations, below minimum wage salaries, negation of trade union rights, underage workers and instances of land grabbing with negative impacts on wellbeing and the environment.” All of which demonstrates that, if produced under these conditions, ethanol is anything but sustainable and comes with serious environmental and social impacts.