In 2009, in the middle of the financial and economic crisis, Europe was awakened by the fact that it was losing industrial significance to emerging economies. To counteract, the European Commission launched the concept of Key Enabling Technologies (KETs), new technologies that should result in the reindustrialization of the Old Continent, stimulate competitiveness and generate jobs, growth and wealth in the economy. Six technologies were selected and among emerging technologies such as nanotechnology and micro-electronics, biotechnology was put forward as a cutting edge technology.

In 2009, in the middle of the financial and economic crisis, Europe was awakened by the fact that it was losing industrial significance to emerging economies. To counteract, the European Commission launched the concept of Key Enabling Technologies (KETs), new technologies that should result in the reindustrialization of the Old Continent, stimulate competitiveness and generate jobs, growth and wealth in the economy. Six technologies were selected and among emerging technologies such as nanotechnology and micro-electronics, biotechnology was put forward as a cutting edge technology.

The Death Valley

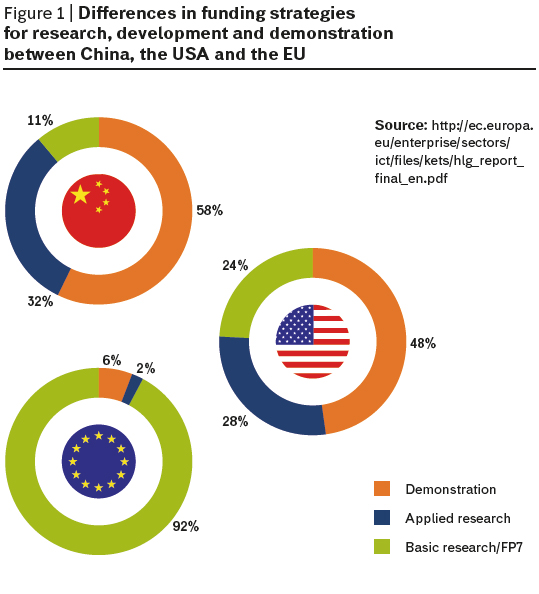

In the framework of the KET assessment study, executed by a high-level expert group, the EC investigated what was hampering the implementation of industrial biotechnology in sectors such as the energy, chemical and food-industry. One of the main observations in that report: The Death Valley, i.e. the phase where many prototype processes or products fail when going from research level to market entry and the lack of public funding for scale-up and demonstration activities to avoid this Death Valley. Compared to the other two economic superpowers in the world, the USA and China, Europe was supporting hardly any scale-up and demonstration activities (figure 1).

With the results of the assessment report in hand, the EC took action. Several new funding instruments were created, e.g.:

- Horizon2020, which in comparison to its predecessor FP7, in general will focus more on the collaboration between academia and industry;

- within Horizon, the special Public Private Partnerships BBI (Bio-Based Industry) and SPIRE (Sustainable Process Industry through Resource and Energy efficiency) with financial support for pilot and demonstration activities;

- also within Horizon, the SME instrument, a program to support small and medium-sized enterprises to get their developments faster to the market.

Hence, so far, so good, the financial support from the EC for pilot and demo activities is available. What else is hampering industrial biotechnology and more in general the bio-based economy to take off? Well, although SMEs and large companies can obtain financial support to scale-up their processes, for many of these companies and especially for SMEs, piloting is not the core of their activities. SMEs typically do not have the infrastructure to accommodate pilot lines, nor have the skilled personnel to run the tests. To obtain faster learning curves and shorter time to market, these activities are better outsourced. To allow this outsourcing, the necessary pilot infrastructure should be readily available, and companies should have easy access, without conflicts of interest with the organization or company that is running the pilot plant. Furthermore, the infrastructure available should be diverse and comprehensive, to allow the scale-up of a wide range of processes; finally, the pilot plant organization should have a critical mass of people to cover the many aspects of the bio-based economy.

Hence, so far, so good, the financial support from the EC for pilot and demo activities is available. What else is hampering industrial biotechnology and more in general the bio-based economy to take off? Well, although SMEs and large companies can obtain financial support to scale-up their processes, for many of these companies and especially for SMEs, piloting is not the core of their activities. SMEs typically do not have the infrastructure to accommodate pilot lines, nor have the skilled personnel to run the tests. To obtain faster learning curves and shorter time to market, these activities are better outsourced. To allow this outsourcing, the necessary pilot infrastructure should be readily available, and companies should have easy access, without conflicts of interest with the organization or company that is running the pilot plant. Furthermore, the infrastructure available should be diverse and comprehensive, to allow the scale-up of a wide range of processes; finally, the pilot plant organization should have a critical mass of people to cover the many aspects of the bio-based economy.

At BBEPP Celtic Renewables will test its process to turn whisky by-products into biofuel

Celtic Renewables, a spin-out company from the Biofuel Research Centre at Edinburgh Napier University, signed last June an agreement with Bio Base Europe Pilot Plant to undergo next stage testing of its process to turn whisky by-products into biofuel that can power current vehicles. The partnership, which will allow the company to develop its technology at BBEPP, has been made possible by second round funding worth €1.5 million, including more than €1million from the UK Government, to help meet its ambition of growing a new €125 million-a-year industry in the UK.

The Scottish company, which is the first company to trial biobutanol technology at the Belgian demonstrator pilot facility, has already proved the concept of producing biobutanol from draff – the sugar – rich kernels of barley which are soaked in water to facilitate the fermentation process necessary for whisky production – and pot ale, the yeasty liquid that is heating during distillation. It will spend the next few months seeking to replicate work done in its Scottish laboratory at an industrial scale.

BBEPP

This is exactly the philosophy the founders of Bio Base Europe Pilot Plant had in mind when launching their initiative in Ghent, Belgium in 2008. Not surprisingly in Ghent, the city where biotechnologists and pioneers Prof. Marc Van Montagu and Jeff Schell discovered the gene transfer mechanism between agrobacterium and plants, which meant the onset for plant engineering in the world and allowed Ghent to position itself as a hub for green biotechnology and later also for red and white biotechnology (respectively food biotechnology, pharmaceutical and industrial, ed.). With financial support from the Port of Ghent, The Province of East-Flanders, Flanders, The Netherlands and Europe, more than 20 million euro was invested in pilot infrastructure at Bio Base Europe Pilot Plant over the years.

In general, Bio Base Europe Pilot Plant is there to close the critical gap between scientific feasibility and industrial application of new biotechnological and/or bio-based processes. It enables companies to assess actual operating costs, specific strengths and weaknesses of new processes and this before costly, large-scale investments are made.

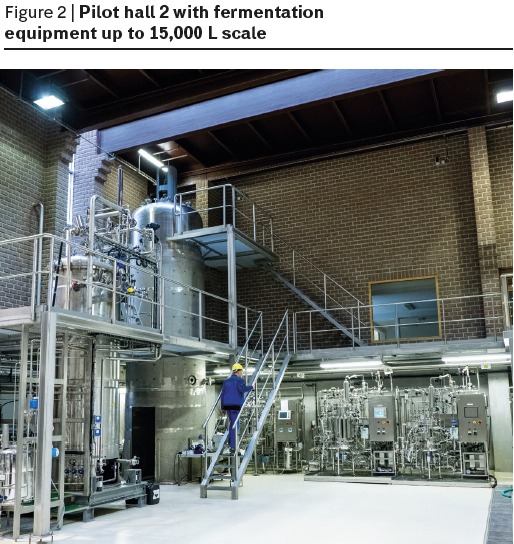

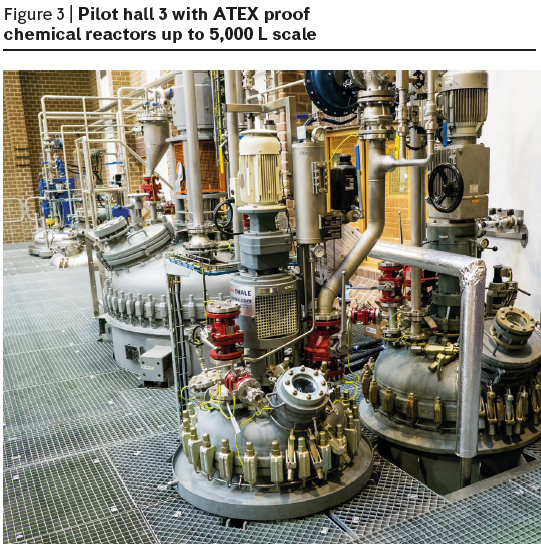

Bio Base Europe Pilot Plant is situated in the Port of Ghent, where an existing building was converted into a pilot plant. BBEPP functions as an open innovation pilot plant that covers the whole value chain from green resource to final product under one roof. With pilot equipment for pretreatment of biomass, fermentation, biocatalysis, green chemistry and downstream processing, it covers a very wide range of processes. The facility consists of three pilot halls, laboratories and a maintenance hall. The first pilot hall is dedicated to pretreatment and biocatalysis and has multiple reactors up to 8 m3 scale, the second pilot hall is the industrial biotechnology hall with fermenters up to 15 m3 scale (figure 2) and the third hall is an explosion proof or ATEX-conform pilot hall with chemical reactors and extraction equipment up to 5 m3 scale (figure 3). The different modules can be connected in a very flexible way, so that different pilot lines can be set up straightforwardly.

BBEPP is involved both in publicly funded projects (e.g. Horizon2020 or national funding) partnering with research institutes and companies in larger consortia, as well as in privately funded projects collaborating on a bilateral basis with industrial partners. In 2013 and 2014, BBEPP carried out respectively 44 and 38 bilateral pilot projects for industry, as such giving an important boost to companies to bridge the valley of death.

Award Winning

The growth and success of Bio Base Europe Pilot Plant has not been unnoticed by the European Commission. In the framework of the multi-KET pilot line project, BBEPP has been awarded as demonstrator pilot line for the KET biotechnology. It shows that the open-innovation character and the concept of shared facilities, are to be seen as an example of how a pilot plant should be operated. As a strong believer in the bio-based economy, I sincerely hope that this acknowledgement demonstrates the significance of pilot infrastructure and that we, thanks to this support, will further enable the development of bio-based processes and products and boost the bio-economy sector as a whole.

Info