At first glance it seems like any terrazzo tile but it actually is a mix of cement and building waste: shingle fragments, broken bricks, ceramic shards. So far EcoTiles – that is the name of the eco-tile – is just a prototype stemming from a research project between university and private companies, but the objective is to market it soon. Compared to traditional terrazzo and ceramic tiles, eco-tiles use a vast array of secondary raw materials derived from construction industry waste (including marble fragments, ceramic materials) and glass. EcoTiles base is indeed made of everything that – normally – in the construction industry is landfilled; the top part is made of recycled glass shard.

Moreover, even the cement used is ecological, with up to 30% content of recycled secondary raw materials.

Actually, eco-tiles are derived from those traditional terrazzo tiles, one of the first flooring materials created by using marble and stone processing waste, bound together with cement and dyed with natural pigments. Terrazzo eco-tiles are mainly used for floor coverings, but terrazzo is also a modern material and an ideal product for bioarchitecture, which lured the market, thanks to the endless possibilities offered in terms of creativity.

EcoTiles, ecological tiles

EcoTiles designed two prototypes.

- Standard – presented at Cersaie 2016 – where up to 70% of raw material is replaced by recycled secondary raw materials and C&D waste (Construction and Demolition waste). It consists of a double layer: a foundation and an upper noble treading layer.

- Design, a product extremely pleasing to the eye conceived to meet the demand for architectural uses in particular. Thanks to the use of recycled glass and pigments added to the cement, it can be manufactured in a vast range of colours.

EcoTiles tiles are currently being tested for quality and performance in order to meet UNI EN 13748/1 regulations, the CE marking of tiles defining the standard of terrazzo indoor flooring. Moreover, EcoTiles take part in meeting the criteria of the voluntary certification system of the environmental sustainability of LEED buildings (Leadership in Energy and Environmental Design), allocating points to buildings according to, amongst others, the use of green materials. Eco-tiles are LEED compliant, i.e. they contribute to obtaining LEED credits while contributing to the overall sustainability of the building. Last, they meet the demands of green public procurement to optimize and turning public administration expenditure and the eco-innovation market greener.

How an eco-tile is produced

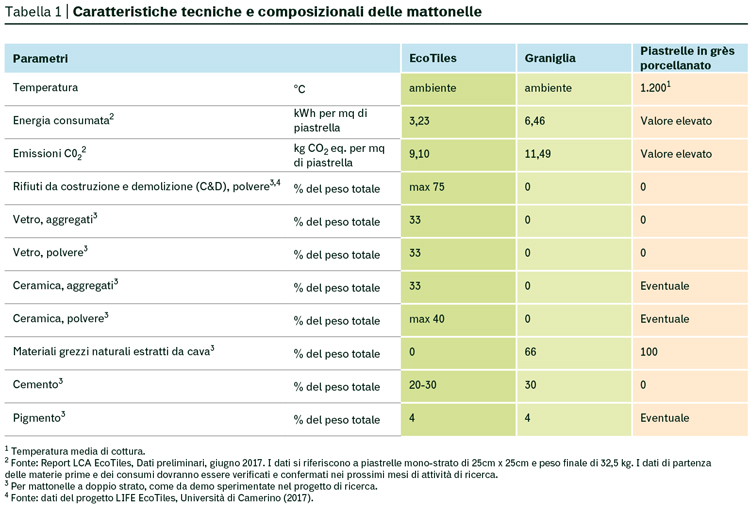

Terrazzo tiles were created as a cheap product, both for the type of raw materials used and because they are not fired at high temperatures. So, their production is already characterized by low energy consumption and reduced CO2 emissions, far lower compared to the production of ceramic tiles (table 1).

Compared to traditional terrazzo tiles, EcoTiles show an even more sustainable production process, while maintaining the same technical performance. Indeed, the use of waste materials not only further reduces the environmental impact of the production compared to ceramic, but the use of energy is limited to low energy consumption operations such as: preparation of the cement mixture, distribution of materials in moulds, mechanical pressing, drying, polishing and packaging.

EcoTiles production goes through a series of steps: selection of utilized waste and chemical and physical characterization of secondary materials, from the applicability of intermediate materials, up to the choice of size/colour/quantity of products to manufacture. In the production process, a new type of press and an innovative method for aging (drying) have been patented. The so-called microchamber method enables tiles to dry in their own humidity and heat: such production technique, unlike that of traditional terrazzo tiles where it is necessary to saturate the aging chamber with steam, uses about 50% less energy, from 6.46 to 3.23 kWh per square metre of tile (Report LCA EcoTiles, preliminary data, June 2017) as well as less water.

|

|

Terrazzo tiles by Grandinetti Srl

|

EcoTiles are proof of the possibility of producing tiles preformed with recycled material up to 70% of their weight. The secondary raw materials used derive – as mentioned above – from recycled glass and C&D waste. Glass waste must adhere to the cement mixture and therefore must be free from impurities (paper, plastic, metal etc.) and pristine. As a result, selecting suppliers of raw materials able to guarantee a high quality standard is key. In addition, chemical composition (absence of lead and other potentially toxic metals), must be identified, as well as the colour and the size of granular employed. EcoTiles resistibility to abrasive environments is high, while a terrazzo tiles’ disvalue is represented by increased absorption of acids and fats compared to ceramic tiles, unless protective layers are applied.

What Politics Can Do

The first step to promote the use of eco-sustainable products is improving its acceptance by consumers, spreading knowledge on benefits deriving from the adoption of production methods with lower environmental impact. To do so, the Eco-label proposal could be promoted, especially for flooring. On this subject, please bear in mind that the EU voluntary Eco-label – the so-called “Flower” – came into force by 880/92 EEC regulation of 23rd March 1992 and revisited by EC regulation 1980/2000 of 17th July 2000 (Ceramica Italiana, 2016). The eco-label testifies that the product has a limited environmental impact throughout its whole life cycle (LCA, Life-Cycle Assessment). Even further popularization of LEED certification could make eco-sustainable products more easily recognizable by consumers.

There are a number of possibilities to promote secondary raw materials recycling and reusing in the construction sector:

- funds for the adoption of techniques for selective demolition;

- reduction of tax and red tape streamlining for the purchasing of secondary raw materials (transport);

- use of Building information modelling (BIM) to monitor the buildings’ whole life cycle.

In order to create a market for secondary raw materials it is imperative to create a network of operators for C&D waste collection, disposal and transformation. In order to corroborate such policy, the supply of pure and quality secondary raw materials should be encouraged. Without European standards it is difficult to promote recycling competitiveness.

Even streamlining environmental rules and regulations on the one hand and their stricter application on the other encourage an increase in the use of secondary raw materials. By contrast, the building sector has always had access to virgin raw materials at a very low price, with negligible royalties paid to Regions. As a result, investing in waste recycling is not very luring (Pergolizzi, 2016). Moreover, at EU level, the low costs for landfilling jeopardized alternative uses.

Hopefully the use of materials with high environmental standards will be taken into consideration both at national and EU levels. This can be achieved for example by promoting the adoption of minimum quantities of recycled materials to be used in new buildings.

Ecological Cement

Experimental studies highlighted the fact the cement employed in eco-tiles can be partially replaced by ceramic waste material, finely ground (Raval, et al., 2013; Perugini, et al., 2014; Mas, et al., 2016) which can contribute up to 15% of the tile’s weight. Such replacement makes for a cement with pozzolanic properties and an ecological connotation compared to traditional cement, thanks to the possibility to reuse waste material. The aim is to keep cement properties and tiles characteristics unaltered. Besides, with this innovative methodology, a business production costs can be cut, thanks to reduced use of cement representing the most costly component of tiles. The use of secondary raw materials obtained from waste enables to avoid the extraction of new raw materials from quarries, therefore reducing energy consumption and the production of new CO2 emissions. From a company’s point of view, limiting energy use and CO2 emissions represents a reduction of production costs.

An interesting application is then offered by the possibility to enrich cement making up the terrazzo tile blend with TX Active photo catalytic active principle (Italcementi Group) able to abate air pollutants.

|

|

Terrazzo tiles by Grandinetti Srl

|

Synergy between Universities and Industry

The idea of an ecological tile met the interest of the EU that funded LIFE14 ENV/IT/000801, a two-year project. The funds enabled to support both research, carried out within the university, and innovative industrial production carried out by private companies. Two young researchers and two PhD students participated in the project that gave them excellent experience of industrial research and European planning.

The research was carried out by researchers from the mineralogy group of the University of Camerino, dealing with chemical and structural characterization of minerals and rocks, glass, pigments, ceramic and cement. The industrial partner to the project is Grandinetti Company, a leading business in the production of terrazzo tiles. The experience and inclination to innovation helped the company to establish itself on the national and international markets of conglomerates and coverings.

Market Demand

The main types of customers potentially interested in EcoTiles are:

- residential sector users;

- suppliers of intermediate raw materials (cement);

- suppliers of services of the building sector (construction companies, architects, engineers etc.).

The main factors that can influence market demand of ecological tiles are represented by price (often higher than that of traditional products), by technical performance, by aesthetic value, by the level of craftsmanship of tiles and by that of environmental sustainability of the production process. As for costs, it must be noted that if the cost of terrazzo tiles is higher than that of ceramic ones, that of installation is lower thanks to less labour required.

Moreover, eco-tiles can be characterized as a customised and tailored product, meeting individual needs of customers. The differentiation originated by the level of craftsmanship of the production influences consumers’ choice. Every processing phase, even if it stems from industrial innovations, is to a certain extent still manual and therefore products are one of a kind.

A further differentiating factor consists in the recognition by consumers of the nature of environmental sustainability of the production method. Last, the potential of circulation of ecological tiles and the production process is high because the technology is widespread and businesses are eager to innovate.

EcoTiles, www.ecotiles-lifeproject.eu

Leed, www.usgbc.org/leed

Info

Bibliography

Ceramica Italiana 2016 www.laceramica italiana.it/en

EcoTiles, www.ecotiles-lifeproject.eu

Grandinetti Srl 2017 (www.grandinetti.it/en), EU LifeEcoTiles research project partner

Mas M.A., J. Monzó, J. Payá, L. Reig, M. V. Borrachero “Ceramic tiles waste as replacement material in Portland cement,” Advances in Cement Research, 28 (4), 221-232, 2016

Pergolizzi A., “Children of a Lesser God,” Renewable Matter, n. 11, July-August 2016, www.renewablematter.eu/art/234/Children_of_a_Lesser_God

Perugini V., E. Paris, G. Giuli, M. R. Carroll, “The Use of Urban Ceramic Wastes in Eco-Sustainable Durable Cement,” Proc. International Conference 34th Cement and Concrete Science 14-16 September 2014, Sheffield UK

Raval A. D., I. N. Patel, J. Pitroda, “Ceramic Waste: Effective Replacement Of Cement For Establishing Sustainable Concrete,” International Journal of Engineering Trends and Technology (IJETT), 4, 6, 2324-2329, 2013

Top image: EcoTiles Unicam, glass