The future may be two-dimensional. At least, the future of materials.

Since 2004, when the two Russian physicists Gejm and Novosëlov succeeded in isolating the first monoatomic layer of graphene, starting from the graphite tip of a simple pencil, the Pandora's box of 2D materials has been opened: an extended family of atomic lattices with sci-fi-like properties, which until then were considered inaccessible. Between daring experiments, research of funds and technical obstacles, the race to the killer application for graphene and its siblings has thus begun, promising solutions in various fields that are not only more performing than the current ones, but also more energy efficient and circular.

We had a chat about this with Camilla Coletti, enthusiastic coordinator of the research line “2D Materials Engineering” and of the Graphene Lab at the Italian Institute of Technology.

What are two-dimensional materials? How can we imagine them?

The concept isn’t self-explanatory. Two-dimensional materials, such as graphene, are literally materials that have a thickness of one atom. We can imagine a sheet with the thickness of an atom, so thin it appears to be invisible. This is precisely why we were so late in discovering its existence.

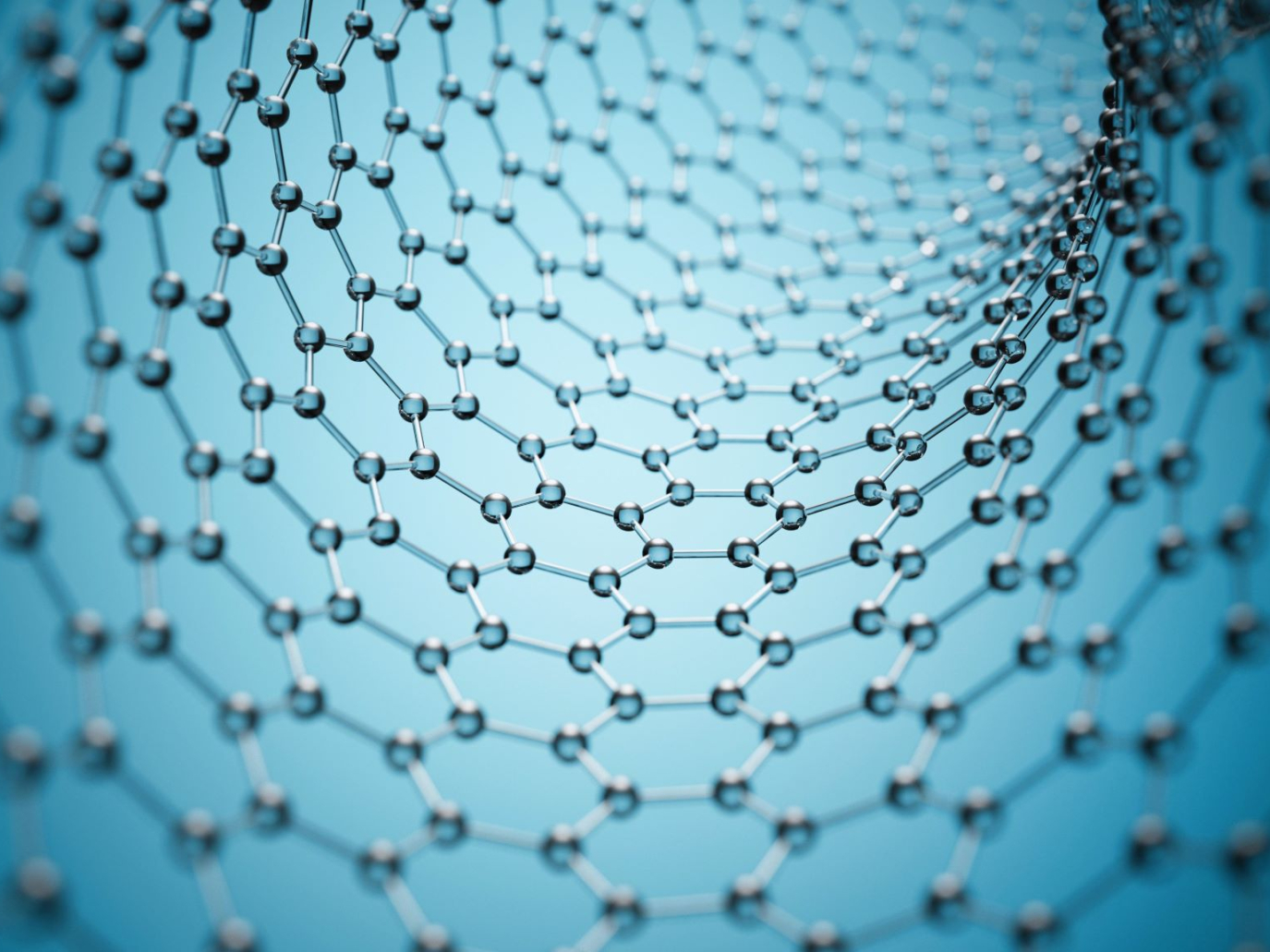

Graphene can be defined as the “mother” of all 2D materials and of allotropes of carbon: think of graphite, carbon nanotubes, fullerenes, all materials already studied during the twentieth century. Graphite is nothing more than a superposition of layers of graphene, stacked one on top of the other; by curling graphene on itself we obtain the nanotube; if we squeeze it into a ball we get a fullerene.

But why did it take so long to discover graphene?

First of all, because we lacked the methodologies to be able to see something so thin and transparent. In reality, the right technique existed, but what was perhaps an even more important obstacle was that this material was thought to be unstable from a thermodynamic point of view. This means that detaching and isolating it from graphite, for example, would make it curl on itself and therefore it wouldn’t exist as a sheet of atomic thickness.

The discovery of graphene, which awarded the Nobel Prize to the Russian physicists Andrej Konstantinovič Gejm and Konstantin Sergeevič Novosëlov, is one of those stories that is almost unbelievable for the randomness and simplicity with which it happens…

It was a discovery born from the desire to go beyond what is believed possible. In the world of scientists, on Friday evenings, instead of going out for a drink, they enjoy doing “weird” experiments. So these two Russian scientists decided, one Friday night in Manchester, to try exfoliating the tip of a pencil with scotch tape, over and over again, in a repetitive motion, to see if it was possible to isolate a single layer of graphene. They finally succeeded and won the Nobel Prize. People have often gossiped that the prize was awarded too hastily, for a childish experiment. But in reality, the two scientists have not only isolated graphene, they have studied its properties: this was what changed everything.

What are then these properties?

Graphene is a structure in which carbon atoms are arranged in a honeycomb, hexagonal shape. There is nothing exotic about this: graphite is the same thing, except it’s built by many layers of graphene one on top of the other. The possibility to have exotic properties with graphene had already been studied and predicted, but scientists thought that in nature it would be impossible to isolate a 2D material without it disappearing instantly. When they succeeded, the properties found are really exceptional. That's why people started to talk about graphene as the “wonder material”.

First of all we can say it’s a playground for physicists. In this material, in fact, electrons, charge carriers, travel at a relativistic speed, that is comparable to light speed. Many of the theoretical predictions made at the time of Einstein, which were not verifiable because there was no suitable material to verify them, have finally found an experimental platform in graphene.

Then, of course, people have started thinking about practical applications. These very fast electrons open possibilities to design very fast computers: the dream of graphene inside was born, which means the existence of computers with graphene processors instead of silicon. A thing that then turned out to be problematic, because graphene always leads, it has no “on” and “off”. Therefore, in the 17 years since its discovery, the vague graphene computers have not been realized and probably will not be the application of choice of this material.

Going back to 2D material properties…

The main property is the fact that its charge carriers travel at incredible speed, approaching the speed of light. Practically these electrons move almost without encountering resistance, and this feature also determines the property of super conduction.

Then there is the transparency: 97% of light in the visible spectrum passes through it.

In addition, graphene is an incredibly flexible material but at the same time it’s also very resistant: as strong as diamond but as flexible as plastic. In short, we could do a lot of interesting things with it.

What are the critical points when it comes to working with these materials?

As we were saying, we have the problem of the of “on and off”. From the point of view of practical work, the first problem is of course the fact that the material is so thin that you need a trained eye to see it even under the microscope.

The other big problem has been trying to produce it on a large scale. It's one thing to have a flake, a sheet of paper with a diameter as thin as a hair: if you're in a research lab, you can have fun making a small device and see how well it works. But if we talk about applications, with such infinitesimal dimensions you can't do anything. So one of the first difficulties that scientists tried to overcome was to produce graphene in a scalable way while maintaining its properties: with the same crystalline quality, with all its regular hexagons, without missing an atom or finding something else instead of carbon. It wasn't easy at all, but a lot of progress was made early on, and there were several approaches that allowed us to get high-quality graphene “grown” on various substrates.

“Grown”?

I say “grow” because that's the method we use in our labs at IIT and it's one of the most classic ways to obtain it. You use a circular plate, which we call wafer, to deposit graphene on it. The type of substrate is chosen according to the final application and can be silicon, silicon carbide, sapphire, copper or any other material typically used in electronic applications. The wafer is placed in a large oven heated with methane at temperatures above 1000C and after a few minutes the reaction called “chemical vapor deposition” (CVD) takes place: in practice, the carbon from the methane is deposited on the substrate forming the graphene. At the end of the process we cool the oven and take it out. Most of the time you can't see anything with the naked eye and you have to check with spectroscopy or microscope if you have obtained a perfect monolayer of graphene.

Are there other ways to get the graphene?

Yes, there are, for example, manufacturing processes that start with graphite: by centrifuging it at ultrasonic speed in a solvent, “inks” are obtained, which can then be literally sprayed and mixed with other materials to strengthen their basic properties. They are ideal for low-tech applications, such as helmets and rackets, and so this system has explored a lot in recent years and has enabled the production of products that are already on the market.

The oven system, on the other hand, allows us to have very high quality material, pure and not in solution form. Once obtained, we manufacture devices, for example for data transmission, which prove to be very efficient, since graphene works well as both transmitter and receiver.

Graphene on foil - ph IIT

Why are these building blocks of photonics made from graphene so interesting?

Covid, if there was any need, has shown us how much we need data transmission. Demand has become enormous and now we have reached a doubling of bandwidth every two years, but this must come at the same cost, energy consumption and footprint, i.e. the size of the devices. Demands that we can no longer keep up with existing technologies: in electronics we have arrived at the minimum size achievable with silicon devices and in photonics we have arrived at the maximum possible achievable with the materials we use. We need new materials.

Graphene is interesting in this field first of all because it has the ability to convert light energy into electrical signals and does so in an energy efficient way. It allows us to make devices that transmit and receive with low energy consumption and outstanding performance, wider bandwidth, very small size. The cost is also promising, because atomic-thick monolayers can be ported to existing photonic platforms without asking companies to change all their production lines.

It's an interesting prospect also in regard of the possibility of replacing critical raw materials such as the so-called rare-earth elements…

Certainly a carbon-based material is a more sustainable solution, even from the point of view of e-waste pollution, which is becoming a big problem.

Since we are dealing with carbon, is it possible to hypothesize CO2 capture processes from which to produce graphene?

Using CO2 instead of methane is actually one of the first solutions we thought of, but we had to stop because of technical limitations of our machinery. However, there is already research using different types of waste, organic products and vegetable oils to obtain carbon from which to produce graphene. The quality is not stellar yet, but certainly these processes will be refined in the near future.

Can we imagine a circular economy of graphene, then?

Yes, the possibilities are there. It's all about being able to demonstrate not only that it can be done – because we already know this – but that it can be done while maintaining the high quality of the material obtained.

Above all, my dream and the dream of those who work on graphene is to find the so-called killer application, that is, the important application that can really change something in people's lives. Without detracting from low-tech products that are already on the market, such as rackets, bike tires or others, I would like to see graphene in an application capable of revolutionizing our lives for the better. We could have, as I said, widely used technology for faster and greener transmissions. If we imagine such a landscape, having the ability to produce high-quality graphene with circular processes would be ideal.

Speaking of green applications, there are also graphene devices to purify water currently being studied…

Yes, graphene has shown to have possible interesting applications and good performances in this field as well. Being a very versatile material, depending on how it’s processed, it can become either highly impermeable or porous, and in this case it lends itself precisely to absorption.

We have talked a lot about graphene, but it’s not the only 2D material. After its discovery, a universe of new two-dimensional materials seems to have opened up: how many are there?

There are so many of them. There are theoretical studies that speak of hundreds and hundreds of materials, but obviously in practice those that we can synthesize, isolate and study are way fewer. The ones that the most interest is focused on at the moment are graphene's white brother, boron nitride, and transition metal dichalcogenides (TMD). Boron nitride is made exactly like honeycomb graphene, but instead of having all carbon atoms, there is an alternating boron atom and nitrogen atom. Unlike graphene, it is an insulating material, so putting them together makes dreamy electronic devices.

Then there is the whole family of transition metal dichalcogenides (TMD) that are formed by a chalcogenic atom (sulfur or selenium for example) and a transition metal such as tungsten or molybdenum: so we have tungsten disulfide, molybdenum disulfide, and so on. These materials are actually three-dimensional, but the layers are so weakly connected to each other that you can exfoliate them and get other 2D materials. The interesting thing is that as three-dimensional materials they have certain properties, but by isolating the single atom or the single layer of atoms, the properties are completely different. For example tungsten sulfide is normally a semiconductor and does not emit light, but in 2D form it is the opposite and you can therefore make a lot of applications in electronics and optoelectronics.

What is still missing and what will be needed in the near future to get to tangible, marketable applications for 2D materials?

Certainly from the point of view of investments, there has been a strong help from the European community with the Graphene flagship project, of which we are part and of which many European countries and institutions are members. This project has made it possible to create synergies between companies and research institutes in order to move rapidly towards the development of practical applications.

What is missing is to be able to identify the best applications among all the possible ones and in that direction continuing to work in a synergistic way with companies and with those who could be the final users of the application. I would say that we are at a good point: if this virtuous circle is not interrupted now, we have good chances to see 2D materials in relevant applications in 5 or 10 years.

Fortunately the interest from the industrial world is there. The problem now is to be able to demonstrate the reproducibility of 2D materials on a large scale: everything we can do on 3 centimeters, we need to do on 15 centimeters. To summarize, now we need reproducibility and market.