|

|

Armando Testa, Pirelli Elephant, 1954 ©Pirelli |

Ecopneus has come a long way in less than three years. It is a not-for-profit consortium business made up of producers and tyre importers that guarantees collection, recovery and tracking of end-of-life tyres (ELTs). It started its activities in September 2011; in 2013 – the last period for which official data is available – Ecopneus already recovered 247,000 tons of ELTs, the equivalent of 70% of the national market of end-of-life tyres. “We could do even better,” states Giovanni Corbetta, Director General of Ecopneus, “for example a growth in the percentage of ELTs destined to matter recovery in relation to those destined to energy recovery would be an important step. It is the European Union that is requesting this, convinced as it is that prolonging the productive use of materials by re-using them, would strengthen UE competitiveness at the global level. Unfortunately, in Italy we have to face a series of bureaucratic, normative and cultural obstacles that contribute to hinder the growth of the market for recovered tyres”.

To try to understand what is happening we have to take a step back. Brussels is pushing towards the development of a circular economy which proposes a different economic model from the past, a model where raw materials are extracted, only used once and then thrown away. According to this new paradigm waste disappears and re-use, reparation and recycling become the norm. The new Commission presided by Jean-Claude Juncker has postponed the examination and decision on this matter until next summer blocking the proposal of the new waste directive (which includes the idea of circular economy) pushed by José Manuel Barroso. This has generated alarm, even though Juncker has announced that by the end of the year a new and more ambitious directive will be presented: unofficial declarations suggest that the new text contains challenging objectives, such as a 50% target of ELTs recycling from 2020 onwards. What impact can this have on the tyre sector?

The environmental benefits already gained thanks to Ecopneus’ efforts are significant. This is confirmed by the “Sustainability Report 2013,” produced by the consortium, which stresses how, through the use of recycled rubber rather than virgin one, total recovery prevented the emission into the atmosphere of 347 million tons of CO2eq. But there is more. As the report suggests, Ecopneus’ effort has contributed to save 3.2 billion kWh of energy, as well as 1.3 million cubic metres of water by reducing the use of virgin rubber in the production cycle.

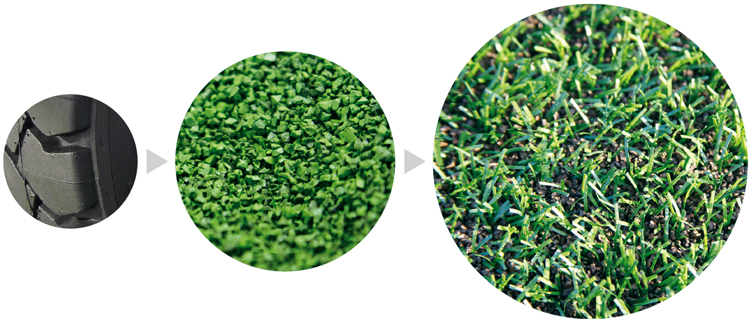

So is everything fine, then? Yes, but only to a certain point. Corbetta explains: “We need to carefully examine the composition of the 247,000 ELTs recovered in 2013 to discover that, out of them, 152,000 were used for energy recovery in cement factories and only 62,000 ended up in the recycling market. Ecopneus is not against the use by cement factories of the so called ‘pile caps’, big quantities obtained from tyre crushing: the fuel obtained by ELTs has a higher energy value compared to pet coke or high quality coal. Also, CO2 emissions are lower than those of fossil fuels, as a big portion of ELTs comes from renewable sources such as natural rubber and part of the textile reinforcement comes from cellulose. But today the EU is asking for something different. It is pushing towards recycling rather than ELTs’ use as an energy source. It is an objective that Ecopneus shares, and it is working hard to promote the use of recycled tyres in the most diverse sectors: from ‘silent’ road surfaces to artificial football fields, from sport floors to children’s playgrounds.”

The path ahead is difficult. Estimates suggest that in 2014 less than a third of gathered ELTs went to matter recovery and two thirds to energy recovery. These percentages need to be reversed by 2020. In this context it is necessary to look at the bureaucratic obstacles stressed by Corbetta. A typical Italian trait is the gap between declarations of principles and their implementation. Politicians, trade unionists, ministerial bureaucrats, all agreed with Janez Potočnik, former EU commissioner for the environment, when he proposed “more ambitious recycling targets to move towards a circular economy with more jobs and sustainable growth”. Or when he declared that “if we want to be competitive we have to make the best use of our resources, reinserting them into the productive cycle instead of sending them to landfill as waste”. Moving from words to actions, though, takes time, even when there is little available.

In this scenario, the example offered by ELTs recycling is important. Ecopneus’ Director General suggests three interventions by the public administration which could favour the re-use of material derived from the treatment of ELTs and stimulate a virtuous cycle for the benefit of communities. As a first step, he suggests the implementation of a fast-track for recycled materials within contracts with the public administration. “A choice,” says Corbetta “that would have three positive results. There would be significant environmental and ecological benefits such as a reduction in CO2 emissions, as virgin rubber would not be used and a correct waste management cycle would be consolidated. The third benefit would be financial: imports of raw materials would diminish with significant advantages for our trade balance, while energy costs would also go down. Furthermore, Europe is asking us to keep inside the union the secondary raw materials considered strategic for its development”.

There is no doubt that the creation of a robust internal market for recycled rubber would also have a positive impact on employment, opening up new market possibilities for companies. “Furthermore, a more active demand,” states Ecopneus’ Director General “would increase the value of ELTs granules and powder that today are too cheap. This low price devalues the product and make the business less profitable and attractive”. In this framework, every obstacle to development could be negative. That is why the lack of an official definition at a ministerial level of recycled rubber as “secondary raw material” or simply “rubber” represents a problem. A matter that is well known at the Ministry for the Environment: it will be dealt with through a provision that will likely include other materials. The regulatory framework could appear secondary, but it’s not. If recycled rubber is not explicitly defined as “secondary raw material” it is officially waste. “It is an important matter,” says Corbetta, “that practically blocks the development of the market generating fear and uncertainty. Let’s just imagine a public administrator that wants to build a road using asphalt modified with rubber powder: a solution that contributes to significantly lower the noise, to longer duration and to better security performances in case of sudden braking and better visibility in case of rain, with a significant reduction in maintenance costs. However, would that administration feel confident of approving such an operation? Would the fear, that tomorrow their decision might get contested by some authority due to the use of a material that comes from waste, contribute to the choice of a more traditional and less efficient material? The possibility of such an intervention is very low, almost non-existent. However, it is a potent fear that could block the market. Why not give our sector a better chance?”

Info