Expo 2015 has certainly brought to the international attention different aspects related to the safeguard of food resources. Among various issues, food waste is particularly important from many points of view. For years several countries have carried out initiatives aimed at reducing food waste, both for ethical reasons linked to a disparity in food distribution between different areas of the planet, and for environmental reasons, as food waste is one significant cause of CO2 emissions.

As of today though, despite more accurate studies and research that describe the problem, significant results are yet to be seen, as final consumers have not become an active part in this system.

From a practical point of view, zero food waste is not an easily reachable target in the short term, as the current productive process and consumption models do not contemplate precise management rules for food waste. However, luckily things are partly changing.

In the last few years, we have witnessed a move towards projects that value waste, also thanks also to research, technology and trials more and more oriented towards environmental sustainability. The main credit goes to companies that transform food waste into new resources, both as a market opportunity and to follow the principles of the circular economy.

|

|

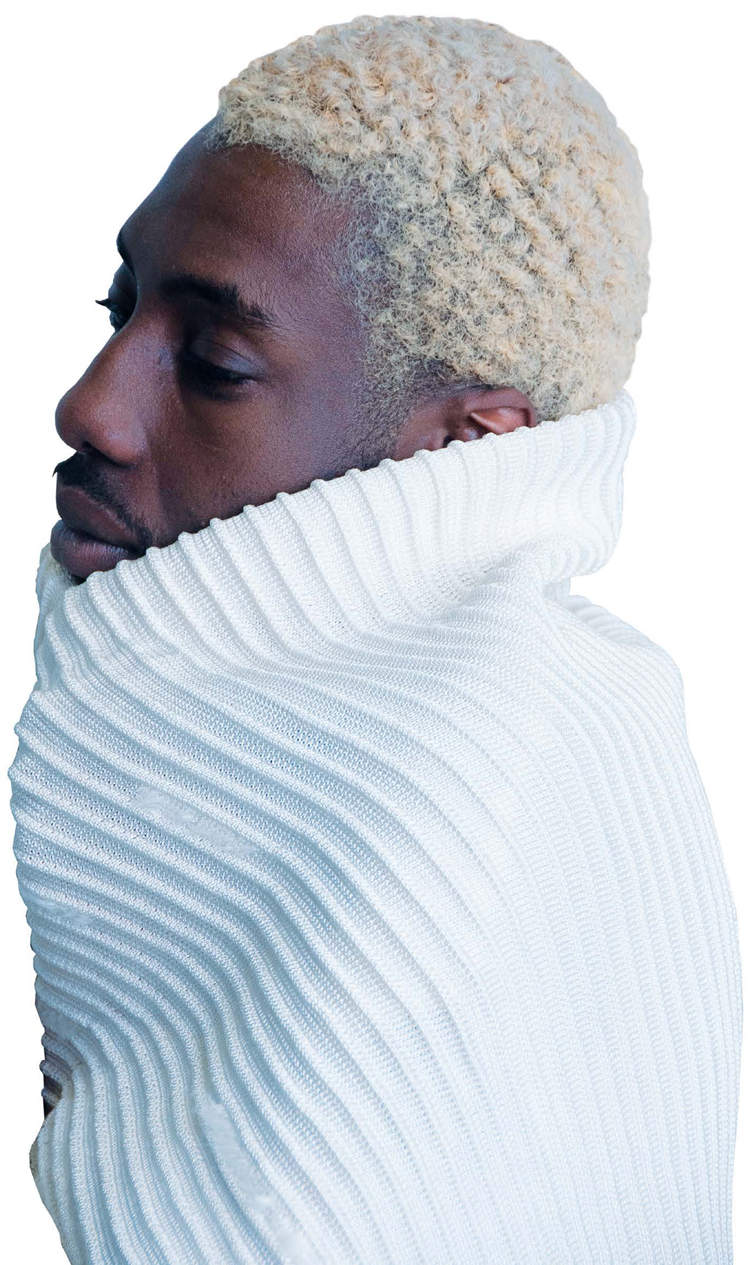

Clothes in Milk

|

This was exactly the objective of Made in Food Waste, a publication which was the result of international research by the International Observatory of Matrec in collaboration with the University of Architecture and Design of Chile: to explain how food waste can become a resource for new industrial products. If properly treated, and in some cases mixed with natural components, food residues have a big potential use and become new materials with traits and properties that can be used in different applications.

|

|

Combine

|

Fruit, vegetables and cereals, after a phase of natural or mechanical drying, are the most widely used products in the production of lamps, bowls, sheets of paper and home accessories. In some cases, the texture of the product imitates designs and shapes of the original fruit, while in other cases the use of a mechanical process and the addition of natural binding materials allows for a printing process for the realization of the final product.

Those recovery processes that from this kind of waste produce a series of yarns used for making clothes are particularly interesting. Instead, with tea leaves, eggshells, sugar, rice waste, mushroom mycelia and nutshells we can make bowls, vases, brushes, shoes and objects for the house.

Coffee grounds too, mainly recovered from cafés, have been used in different ways and for tests in the production of lamps, vases, bowls, cups and yarns for textiles. The coarseness and the colour of the material give the final products a texture, sometimes a dishomogeneous one, which is however very pleasant to the eye and touch.

|

|

Mondongo Shoes

|

Sustainability Scenarios

Matrec, thanks to the International Observatory for Sustainable Innovation, has been collaborating for years with companies, applying development and sustainable innovation strategies to new materials and products. International research and investigation show that, while buying, consumers pay greater attention to products’ social-enrvironmental values, raw materials’ origin and production processes.

In the last few years, particular attention has been given to fish skin which, when recovered at an industrial level and properly treated, has found many uses in the fashion industry and is also used by big luxury brands to produce bags, shoes, accessories and clothing items. There are also products derived from milk casein or from bagassa; shoes, packaging and objects made with coconut fibre; dishes made with bamboo residues, bagassa and sugar cane; sponges in agaves fibre and shoes produced with offal obtained from different parts of a bovine stomach.

Besides being highly innovative, all these products are in most cases very functional, pleasant looking and their natural origin guarantees, almost all the time, a virtuous disposal thanks to their biodegradable and composting characteristics.

Research has also shown how other food waste can be used as natural colouring for textiles and leather. However – it needs to be stressed – this valuing process cannot and must not be interpreted as a justification for a weaker commitment in the effort to reduce the amount of food waste: it is necessary to initiate immediately actions aimed at reducing waste along the whole of the supply chain and activate projects that value the possible final residues.

|

|

Cocolok Shoes: shoes in coconut, latex, bioresin and wool. The coconut sheets are sprayed with natural latex in order to be molded. The bioresin is used to give structure, while the sock in contact with the skin is made with wool felt (United Kingdom).

|

|

|

Agricola: biodegradable and compostable lamps made of waste coming from production and consumption of fruit, vegetables and cereals, treated with different natural binders (The Netherlands).

|

|

|

Coconut Bowls: colorful bowls suitable to contain foods, made of coconut shells smoothed and laquered by craftsmen (USA).

|

|

|

Footglove Earth Sustainable Shoes: collection of casual shoes made of 35% of natural rubber and 10% of rice husk for the sole, recycled PET bottles for internal reinforcement and seams and 57% of recycled coffee for the insole (United Kingdom).

|

|

|

Wasara: biodegradable and compostable single-use tableware line made of 100% renewable materials as bamboo, reed pulp, bagasse and sugar cane scraps from the extraction of juice (Korea).

|

|

|

Blanket: embroidered and knitted blankets made of bagasse residues of sugarcane processing. Bagasse is chemically broken down and extruted to form fibre (United Kingdom).

|

|

|

Saccharum Project: collection of tableware made of refined sugar, bagasse, sucrose, sugarcane fibre and sugarcane ash. All products developed as result of sugar production (United Kingdom).

|

|

|

Cocoform: eggs packaging made of recycled coconut fibres from coconut husk derived from food industry waste combined with natural latex (The Netherlands).

|

|

|

Artichair: a series of indoor furniture made of a 100% biodegradable material derived from parts of cardoon. These wastes, reduced to a pulp, are not used in the biofuel production process (United Kingdom).

|

Info

Top image: Impasto