It started operating in 2002, when Alex Krajete left for California with a degree in chemistry under his belt obtained from the University of Innsbruck. After a PhD at Berkeley University, at the California Institute of Technology (Caltech) in Pasadena the Austrian researcher started investigating the transformation of CO2 into methane by using microorganisms. He struck gold in this research field. So much so that back in Europe, Dr. Krajete carried on his studies turning them into a business, first a one-man company (2011) and then Krajete GmbH (2012), where five more researchers with a PhD joined him. Collectively, they primarily research into the use of CO2 but also into synthesis gas (a blend of carbon monoxide, CO, and hydrogen, H2), for the production of methane as zero emission fuel for motor transport. The methane obtained in this way is a fourth-generation biofuel, in other words its production does not require photosynthesis.

“Fourth generation biofuels – as Krajete researchers point out – are also known as biofuels without biomasses and are based on hydrogenation of CO2 into energy dense molecules (methane, methanol and higher alkanes)”.

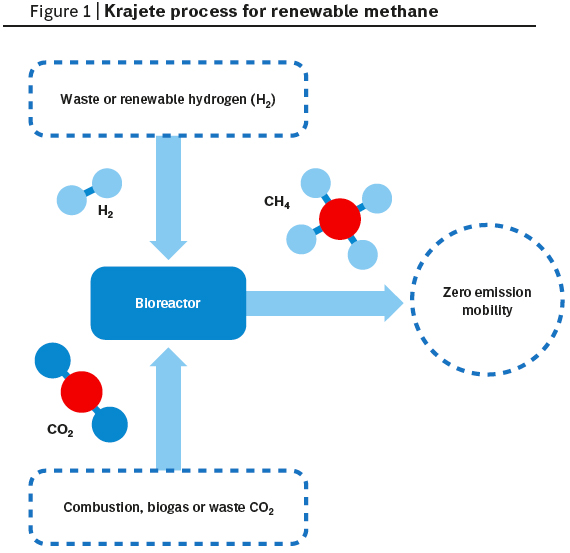

Today Krajete GmbH boasts a series of patents covering the transformation of renewable energy or waste hydrogen into methane (see figure 1).

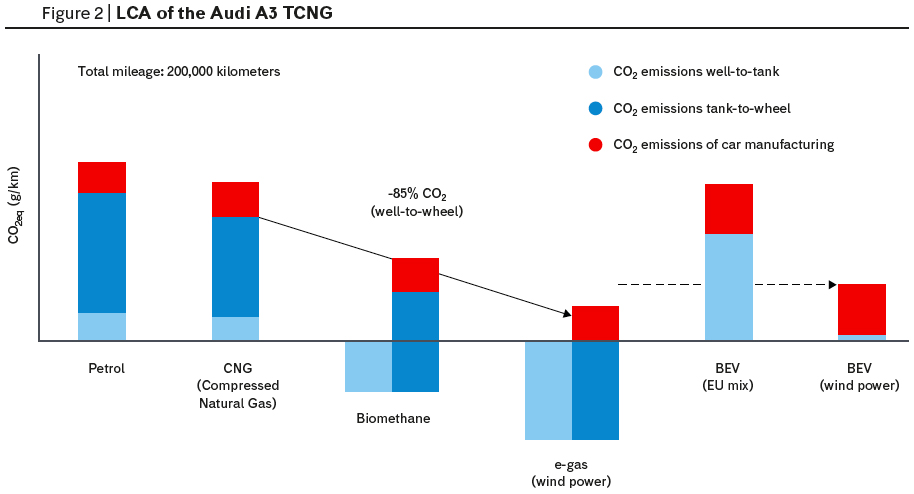

The Austrian start-up operating field is the so called Power to Gas (PtG, see box) through biotechnology, with a robust process able to support both the input of non-purified CO2 (and therefore knocking down the costs involved in the preparation of raw material), and pressure and purity variations in the supply of hydrogen. Such process flexibility enables to use hydrogen from the cracking phase of hydrocarbons, which does not necessarily require production of hydrogen through water electrolysis. Krajete is therefore able to use its biotechnological process both with renewable and fossil raw materials, thanks to the great operational flexibility of his process (see figure 2).

|

|

Results for Audi’s Life Cycle Assessment for CO2 emissions of a synthesis methane-powered car and an electric one powered with renewable energy (copyright Audi 2012). |

Over a three-year period, the company researchers, whose headquarters are based in Linz, managed to identify a series of microorganisms able to turn CO2 and H2 or synthesis gases into methane with high productivity, operation flexibility and robustness and established a starting point to devise a scalable methanation process, with easy manoeuvrability and ideal for solutions nationwide, for instance the upgrade of raw biogas into biomethane or the reutilization of CO2 produced during fermentation for bioethanol and its conversion into biomethane. As a result, the yield per hectare of biofuels is considerably higher, with improved environmental sustainability.

Methanation, a process developed by Linz and Vienna universities within a doctoral theses sponsored by Krajete itself, has been producing methane on a 10-litre scale for over two years, with samples of real gas provided by customers and synthesis gas produced with the most varied purity and contaminants specifications.

The bulk of data collected since the first experiments to date has been the base of a simulation process that has provided further in-depth knowledge of methanation and a good understanding of its performance first as a pilot plant and then as a production one.

Power to Gas

Power to Gas (PtG or P2G) is a recent concept introduced to the general public by Audi. Renewable energy peaks surplus in the electric grid is used to split water into hydrogen and oxygen through electrolysis. Then, in a reaction between hydrogen and CO2, methane is obtained in a chemical or biotechnological catalyst. Methane produced through PtG is also known as e-gas because it is derived from electricity.

“All this – as they like to point out at Krajete – has been standing on its own two feet, that is, without the input of public or private investors, just thanks to the cash flow generated through bilateral contracts with companies interested in this process (mostly car and cement factories and steel plants).”

The Linz-based company targets the motor transport zero-emission methane market. This is why Krajete is focusing mainly on Italy, traditionally one of Europe’s major transport methane markets with over 800 million kilograms of motor transport methane sold in its one thousand refuelling stations and with nearly one million vehicles on the road.

Italy – Krajete assures – is the European leader in the production of methane-powered standard cars (Fiat Group), in the development of methane-adaptation technology (Landi Renzo and Tartarini Auto produce the world’s most advanced adaption kits) and in the aftermarket fitting.

“Zero emission” methane, when used in a methane-powered car, allows to zero CO2 emission in vehicles. A methane-powered car refuelled with renewable methane (biomethane from biogas or PtG methane) has the same CO2 emissions of an electric car powered only with renewable energy (see figure 2) but with the following advantages: costs are significantly lower compared to an electric car (in Europe, the average price of a methane-powered Volkswagen Golf is about € 22,000 while that of an electric Volkswagen Golf is around € 37,000); there are many more methane refuelling stations compared to electric ones for motor transport, and the “recharging time” is considerably shorter (2-3 minutes for a methane-powered car compared to 30 minutes to half recharge a battery in a Tesla Motors supercharger at best, or over 8 hours for a “homemade recharge”).

Krajete GmbH aims at offering an alternative for zero-emission transport thanks to its renewable methane intending to provide users with a solution compatible both with present infrastructure and cars and able to improve air quality in urban areas.

Motor transport methane

Methane is one of the best fuels available on the market, offering numerous advantages compared to traditional fuels. A petrol litre equivalent of methane costs less than half; its octane performance is higher than petrol (120 octanes for methane, 98 for conventional petrol). Moreover, methane enables a 10% CO2 reduction compared to an equal petrol engine, it reduces noise and, more importantly, it does not emit unburnt material or particulate, thus improving the air quality in urban areas. For further information on motor transport methane, please consult the Natural & bio Gas Vehicle Association website (http://www.ngvaeurope.eu).

Info

Image: © Franco Volpato / Shutterstock