They appear as black granules, with the distinctive smell and colour of tyres from which they originate: this is recycled rubber from ELTs.

It is precisely because of its smell and colour that such material is often perceived as something suspicious, dirty or even dangerous. The environment where this rubber is used – in most cases – also contributes to generate more doubts on its healthiness: is a material designed to roll on roads suitable to be used as infill in football fields?

Today, artificial turfs are made of carpets of synthetic grass blades (PE or PP) from 5 to 12 cm long, kept upright by a variety of sand infill and elastic granules, including recycled rubber from ELTs. It is thanks to the presence of ELT rubber – in the past only sand was used – that athletes are guaranteed a higher playing performance on the field.

Over the last 15 years there has been a hot debate on artificial turf: on scientific publications, in international bibliographical analyses and the media. What caused the first doubts about the healthiness of artificial turf using rubber from ELT were the very high temperatures measured in some cases on the surface due to the absence of suitable irrigation and cooling systems. Clearly, with such conditions, a strong smell of rubber is produced, so much so that the first checks were carried out.

An analysis carried out in Norway showed that on some samples – actually the analysed fields were only three – the presence of PAHs (Polycyclic Aromatic Hydrocarbons), phthalates and PCBs (polychlorinated biphenyls). While such substances were detected in minimum concentration that did not pose any risk for human health, the study’s result re-awoke the debate on the healthiness of such materials and the opportunity to use them.

At that stage, to gain a clearer picture of the situation, in various European countries and in the USA, authorities started further investigations over 115 fields and over 150 samples of elastomeric kinds of infill went almost unnoticed. The results were comforting since all analyses showed that the toxicological risk of the infill was quantifiable at levels lower to the threshold value of 1X 10-6, considered by the scientific community “an acceptable risk.”

Unfortunately, the study went almost unnoticed since it was completed only in 2009, i.e. a few years later, when the attention of the media had diminished and directed to more current themes.

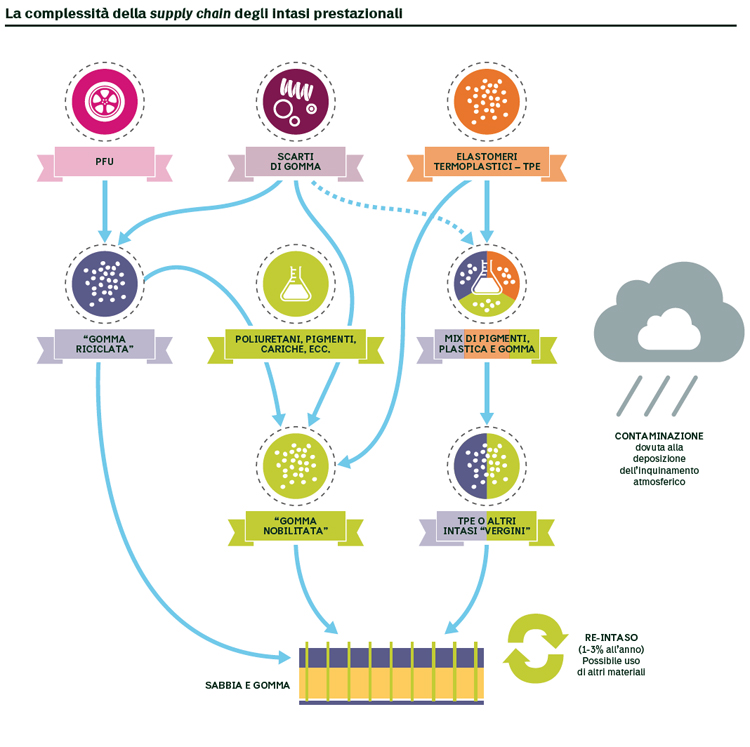

The recycled rubber granules from ELTs are generally called crumb rubber in the USA and SBR (styrene-butadiene rubber) in Europe. In actual facts, one cannot tell with an absolute degree of certainty the provenance of materials taken from playing fields under investigation.

Indeed, first of all, a combination of ELT with other rubber waste/discarded materials from recycling plants, which was a common practice, not so much today, cannot be ruled out. Moreover, there is the possibility that rubber granules from other types of waste (for example the rubber fraction coming from vehicle demolition, brake hoses, washers) may be sold as SBR despite not coming from end-of-life tyres.

The presence of substances not used for the production of tyres and the anomalous data measured by a few researchers on a limited number of samples seem to corroborate such hypotheses and raise some doubts on the representativeness of the analysed materials in the past. Besides, the ban on the use of high aromatic content oils introduced with the new Reach regulation starting from January 2010, changed the compositions of rubber mixes used to produce tyres sold in Europe and consequently in the rest of the world.

Starting from such considerations, in 2014 Ecopneus (an Italian leading non profit company for the tracking, collection, processing and final destination of end-of-life tyres) started a series of scientific analyses and studies to find out the degree of healthiness of recycled rubber from ELTs and the suitability of their intended uses.

Despite such verifications went beyond the duties derived from the extended producer responsibility of tyres, the role carried out by Ecopneus in the promotion of the use of rubber granules and powders is undeniable.

Moreover, Ecopneus also manages the flow of ELTs destined for recycling or energy recovery. Therefore it plays an important role in the market, despite keeping out of the business.

The study lasted over two years: the sampling plan made possible a toxicological as well as chemical characterization of recycled rubber from different types of ELTs. In practice, in five recycling plants over 4,000 ELTs have been classified according to their age and country of origin of tyres. Thanks to such operation, supervised by Bureau Veritas auditors, 70 samples of granules and powders whose provenance was known have been handed to four Italian and foreign laboratories for them to carry out a thorough characterization of the rubber. So, it has been possible to compare the composition of recycled rubber from tyres produced in Europe or outside, before and after 2010.

In the project, Mario Negri-IRCCS – an institute for pharmacological research – measured the content of PAH present in the rubber from ELTs, it assessed its bioavailability and quantified the risks associated with skin and inhalation exposure in the most common scenarios of use.

Meanwhile, the Waste and Chemicals experts have conduced a series of 15 monitoring studies at the football fields with artificial as well as natural turfs in order to ascertain PAH exposure of workers while they were laying the rubber and of athletes during their training matches on the different playing surfaces. Similar monitoring activities have been carried out on 17 road yards during the laying of conventional asphalts and “rubber” asphalts, i.e. with the addition of powder from recycled rubber from ELT.

The analyses showed a reassuring picture confirming the absence of risks for the health of workers and athletes periodically exposed to recycled rubber from ELTs, used both as infill in synthetic turfs as well as an additive for road asphalts. Indeed, the PAH content in rubber is very low in the analysed samples: the total of the eight PAHs classified as carcinogenic substances in the 1 B category is between 5 to 10 ppm (1,000 ppm is the threshold for the CLP classification of mixtures as carcinogenic).

Moreover, tests of migration into sweat and pulmonary surfactants carried out by Mario Negri Institute showed poor bioavailability of such substances that are kept trapped within the vulcanized rubber and therefore not absorbed by the human body, neither through the skin nor through inhalation. Urine tests have also been carried out on workers and athletes to ascertain if due to exposure to rubber there was a variation in the concentration of hydroxypyrene indicating PAH absorption: again, the tests ruled out PAH exposure from ELT rubber.

By way of conclusion, the results of the two-year study and research allow us to define as “safe” the use of recycled rubber from ELTs as infill in playing fields with artificial turf and as an additive for road asphalt. Recycled rubber from ELTs contain limited amounts of PAH, with an extremely limited degree of bioavailability. The results are consistent with a number of scientific publications carried out over the last ten years and represent a clear and reassuring answer to doubts raised in the past on the safety of recycled rubber from ELTs.

Info